Lignosulfonate as a sustainable force in green building plays an important role in the following aspects:

1. Environmentally Friendly

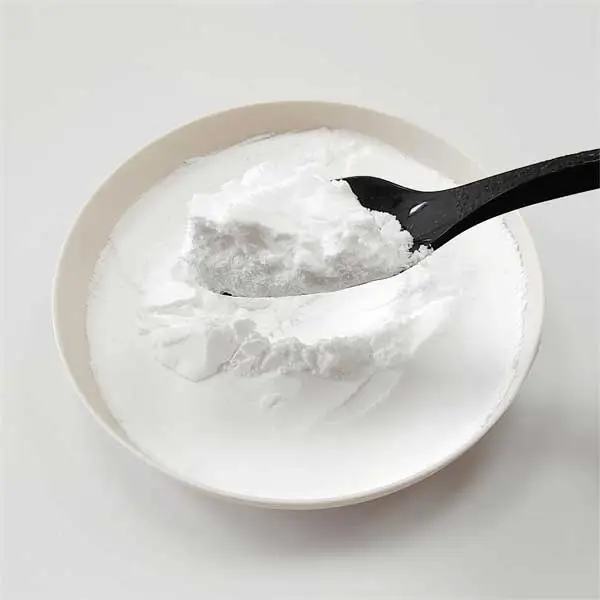

Lignosulfonate is produced from papermaking waste liquid containing lignin through sulfonation, condensation, conversion, and de-sugarization reactions. It is an important product used in the chemical market. It not only fully utilizes renewable resources but also avoids excessive damage to the environment. Compared with traditional chemical additives, lignosulfonate is almost non-toxic and harmless during production and application, providing reliable support for green construction.

2. Effective Concrete Water Reducer

The dosage of lignosulfonate is 0.25-0.3% of the cement quantity, which can reduce water consumption by 10%-14% and effectively improve the workability and quality of the concrete. It improves the workability of concrete and reduces the heat of hydration in the early stage of cement hydration. It is chloride-free and does not corrode steel bars. When used in summer, it can inhibit slump loss. It is generally used in combination with high-efficiency water reducers for better results.

3. Excellent Dispersant

Lignosulfonate is an excellent dispersant and wetting agent in pesticides. During the spraying process, due to the strong dispersing effect of lignosulfonate, the pesticide is uniformly dispersed in the droplets. The droplets fall on the plant leaves and stems and achieve wide and uniform coverage due to the surfactant and film-forming properties of lignosulfonate, thereby achieving a widespread and uniform spraying effect.

Lignosulfonate is also used for the dispersion and filling of dyes and reducing dyes. It has good grinding aid effect, good dispersibility, thermal stability, high-temperature dispersion stability, light fiber contamination, low reduction of azo dyes, and is phosphorus-free, formaldehyde-free, APEO-free, quinoline-free, and biodegradable.

4. Soil Amendment

Lignosulfonate not only works in concrete but also has wide applications in soil improvement. It enhances the coordination between soil particles, improves soil structure and permeability, and creates a better environment for plant growth.

5. Feed Binder

Lignosulfonate can reduce the amount of micro powder in feed, has good particle strength, improves the palatability of livestock and poultry, reduces the return rate of powder, and lowers costs. It can reduce mold loss and increase productivity by 10-20%. The US and Canada allow a dosage of 4.0% in feed.

6. Sustainable Future

Jufu Chemical's Lignosulfonate products have the characteristics of non-toxicity, harmlessness, low cost, and degradability, and they have obvious advantages and broad application prospects. In the future, with the progress of technology, we can foresee that lignosulfonate will continue to play an important role in various fields such as construction, moving towards a more sustainable future.

English

English