Post Date:19,Jan,2026

"Soil Improver" and "Pesticide Enhancer" in the Agricultural Field

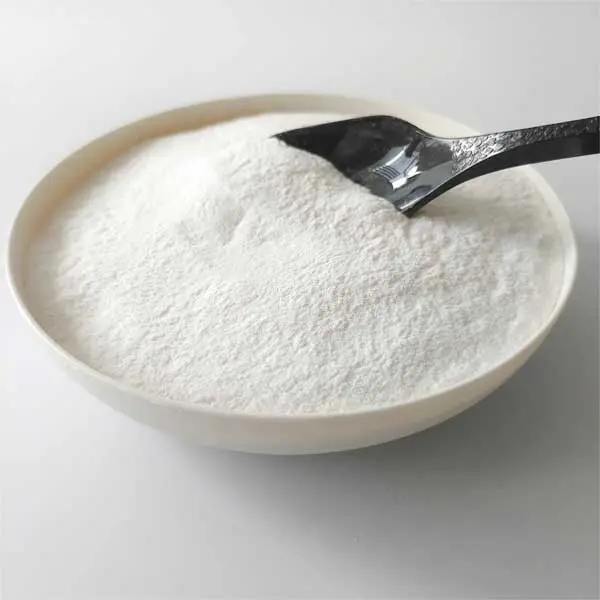

(1) Mechanism of Action of Highly Effective "Soil Improver": Lignosulfonate is an excellent organic colloid. It can combine with small particles in the soil, promote the formation of aggregate structure, thereby effectively breaking up soil compaction and increasing soil permeability and water and fertilizer retention capacity. Chelation and Slow Release: The active groups on its molecules can "grab" (chelate) micronutrients (such as calcium, magnesium, zinc, and iron) in the soil, prevent them from being fixed and ineffective, and slowly release them to plants for absorption, which is equivalent to adding "directional navigation" and "slow-release capsules" to fertilizers. Value: Long-term use can gradually increase the organic matter content of the soil and repair degraded soil. The green approach to the current "storing grain in the land" strategy.

(2) Smart "pesticide synergist" dispersibility and stabilization: In the production of pesticides (especially wettable powders and suspensions), lignin sulfonates are the preferred natural dispersants and stabilizers. They effectively prevent the agglomeration of pesticide particles, allowing them to quickly disperse into a uniform suspension in water, ensuring consistent spraying effects. Adhesion and extended effect: They possess a certain degree of viscosity, helping pesticide solutions adhere more firmly to plant leaves and insect bodies, resisting rain washout, thereby extending the efficacy and reducing the number of applications and dosage. This directly responds to the national call for "reducing pesticide dosage and increasing efficiency."

The "Sculptor" of the Ceramic Industry

(1) Enhanced Plasticity: Adding lignin sulfonate to ceramic clay (body) can significantly improve the plasticity and green strength of the clay. It makes the clay easier to extrude, roll, or injection mold, reducing cracking and deformation during processing.

(2) High-Efficiency Water-Reducing Agent: Similar to its role in concrete, it is also an excellent water-reducing agent in ceramic slurry. It can fully disperse ceramic particles in water through electrostatic repulsion, thereby significantly reducing the moisture required for molding while ensuring fluidity. This not only reduces energy consumption in the drying process but also reduces the risk of drying shrinkage and cracking due to excessive moisture, improving the yield.

(3) Green Substitution: The traditional ceramic industry uses some synthetic organic compounds, while lignin sulfonate, with its natural source, non-toxic and biodegradable characteristics, is becoming a more favored green additive.

English

English