Have you ever wondered how plants maintain their structure or what makes some materials more flexible than others? Well, you can thank lignin for a lot of that! But when it comes to industrial uses, sodium lignosulfonate enters the picture. So, what’s the real difference between lignin and sodium lignosulfonate? Let’s dive into the world of plant biochemistry and explore these two fascinating substances, how they’re used, and what sets them apart.

What is Lignin?

Lignin is an organic polymer found in the cell walls of plants. It’s one of the main reasons trees can grow so tall and why plants have that rigid structure you see in things like wood and bark.

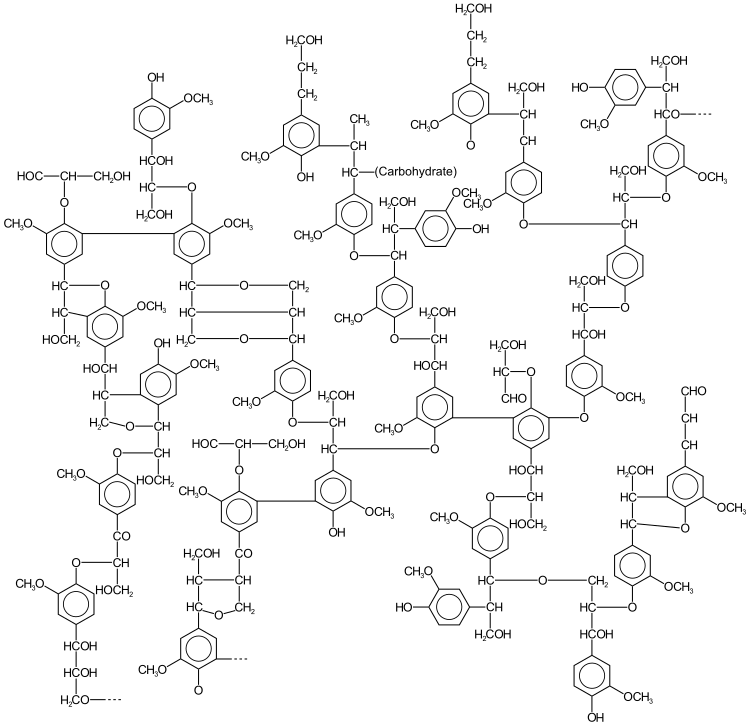

The Basic Structure of Lignin

Chemically speaking, lignin is made up of complex molecules that bind with cellulose, providing extra strength and protection. Its non-crystalline structure makes it durable, giving plants the rigidity to stand up tall and thrive in various environments.

Role of Lignin in Nature

In the natural world, lignin plays a vital role in reinforcing plant cells. Without it, trees wouldn’t be able to stand upright. Lignin also protects plants against pathogens and helps transport water within the plant—pretty essential stuff if you ask me.

Industrial Uses of Lignin

Industrially, lignin is seen as a by-product of the paper and pulp industries. It’s used in creating adhesives, biofuels, and even carbon fibers. However, its full potential hasn’t been tapped yet, so researchers are constantly exploring new ways to utilize lignin in a more eco-friendly manner.

image from Wikipedia.org

What is Sodium Lignosulfonate?

Sodium lignosulfonate, on the other hand, is a modified version of lignin. Think of it as lignin’s industrial cousin that’s been processed for specific purposes.

The Chemical Structure of Sodium Lignosulfonate

Chemically, sodium lignosulfonate is a water-soluble derivative of lignin. The key difference lies in its sulfonate group, which makes it more adaptable for industrial use due to its solubility.

The Process of Producing Sodium Lignosulfonate

Sodium lignosulfonate is created through the sulfite pulping process, where lignin is chemically altered to become water-soluble. This makes it much more usable in various industries where water solubility is a must.

Applications of Sodium Lignosulfonate in Industry

Sodium lignosulfonate is a superstar in the construction, ceramics, and agrochemical industries. It’s used as a dispersant in concrete, a binding agent in animal feeds, and even a dust suppressant. Its solubility and binding properties make it incredibly versatile.

sodium lignosulphonate powder

Key Differences Between Lignin and Sodium Lignosulfonate

Structural Differences

While lignin is a complex, non-soluble organic polymer, sodium lignosulfonate is its water-soluble derivative. This difference in solubility is one of the most significant factors distinguishing them.

Solubility and Chemical Behavior

Lignin’s poor solubility makes it hard to use in some applications, whereas sodium lignosulfonate, with its added sulfonate groups, dissolves easily in water. This makes sodium lignosulfonate more suitable for liquid-based applications like concrete additives.

Industrial Usability

Both have industrial applications, but sodium lignosulfonate’s versatility, thanks to its solubility, gives it an edge in industries that require a liquid medium. Lignin, although tougher to process, has enormous potential in biofuel and material science.

Benefits of Using Lignin

Renewable and Abundant

One of the major perks of lignin is its abundance. Since it’s a by-product of the paper industry, there’s no shortage of lignin available for various applications.

Biodegradability and Eco-Friendliness

Another fantastic feature of lignin is its biodegradability. It’s a natural substance, meaning it breaks down without leaving harmful residues, making it a great eco-friendly option for industries looking to minimize their environmental footprint.

Benefits of Using Sodium Lignosulfonate

Enhanced Solubility

Sodium lignosulfonate’s water solubility opens the door to many uses that lignin alone can’t match. It mixes well in liquid environments, making it ideal for use in concrete mixtures, textiles, and ceramics.

Versatile Industrial Applications

The versatility of sodium lignosulfonate is hard to beat. Whether as a dispersant, binder, or dust suppressant, its usability in various industries is a big plus, making it a go-to material for countless industrial processes.

Potential Drawbacks of Lignin

Difficulties in Processing

Lignin’s complex structure makes it harder to process than more straightforward organic compounds. It’s rigid and tough, which can limit its usability unless chemically treated.

Limited Solubility

Lignin’s poor solubility can be a dealbreaker for industries needing water-soluble components. This limits its potential in certain fields, even though it has great benefits in others.

Potential Drawbacks of Sodium Lignosulfonate

Chemical Processing Requirements

Producing sodium lignosulfonate isn’t the most eco-friendly process. It requires chemical treatments that can be energy-intensive and may create waste by-products if not managed properly.

Environmental Impact

Though useful, the production of sodium lignosulfonate can have a negative environmental impact, mainly due to the chemicals involved in its creation. Striking a balance between its benefits and environmental costs is crucial for sustainable use.

In summary, lignin and sodium lignosulfonate both play crucial roles in industrial and environmental contexts, but they serve very different purposes. Lignin, as a natural polymer, is sustainable and eco-friendly, while sodium lignosulfonate offers enhanced solubility and versatility for industrial applications. Each has its advantages and drawbacks, but with ongoing innovations, both are set to play even bigger roles in the future.

English

English