The influence of temperature and stirring time on the performance of polycarboxylate based high-efficiency water reducing agents

It is generally believed that the higher the temperature, the more adsorption of polycarboxylate superplasticizer by cement particles. Meanwhile, the higher the temperature, the more significant the consumption of polycarboxylate superplasticizer by cement hydration products. Under the combined effect of two effects, as the temperature increases, the fluidity of concrete deteriorates. This conclusion can well explain the phenomenon that the fluidity of concrete increases when the temperature suddenly drops, and the slump loss of concrete increases when the temperature rises. However, during the construction process, it was found that the flowability of concrete is poor at low temperatures, and when the temperature of the mixing water is increased, the flowability of the concrete behind the machine increases. This cannot be explained by the above conclusion. To this end, analysis will be conducted through experiments to identify the causes of contradictions and provide a suitable temperature range for concrete.

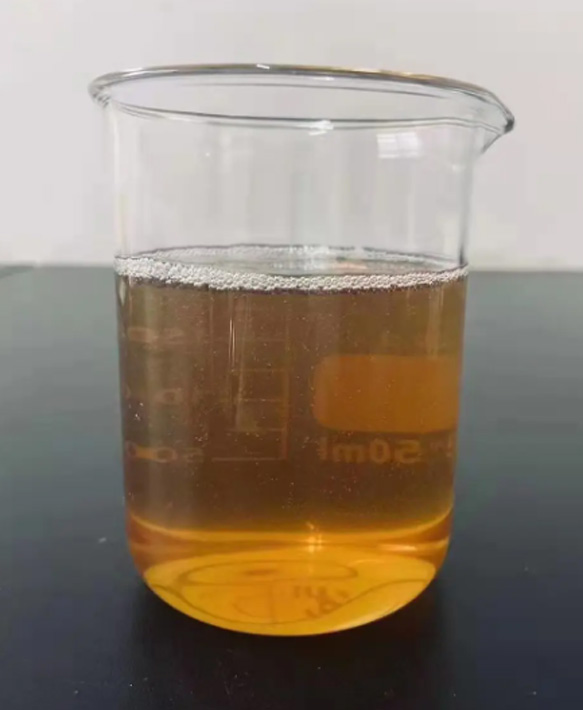

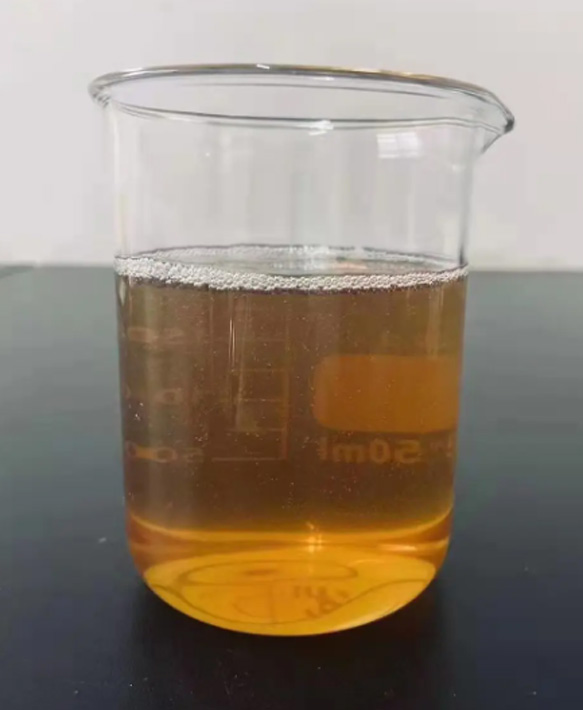

In order to study the effect of stirring water temperature on the dispersion effect of polycarboxylate superplasticizers. Prepare water at 0 ℃, 10 ℃, 20 ℃, 30 ℃, and 40 ℃ for cement high-efficiency water reducer compatibility testing.

Analysis shows that when the discharge time is short, the expansion of cement slurry first increases and then decreases with the increase of temperature. The reason for this phenomenon is that temperature affects both the cement hydration rate and the adsorption rate of high-efficiency water reducing agents. When the temperature rises, the faster the adsorption rate of high-efficiency water reducing agent molecules, the better the early dispersion effect. At the same time, the speed of cement hydration accelerates, and the consumption of water reducing agents by hydration products increases, resulting in a decrease in fluidity. The initial expansion of cement slurry is influenced by the combined effect of these two factors.

When the mixing water temperature is ≤ 10 ℃, the adsorption rate of high-efficiency water reducing agent and cement hydration rate are both small. Among them, the adsorption of water reducing agents on cement particles is the controlling factor. Due to the slower adsorption of water reducing agents on cement particles at lower temperatures, the initial water reduction rate is lower, manifested by lower initial fluidity of cement slurry.

When the temperature of the mixing water is between 20-30 ℃, the adsorption rate of the water reducer and the hydration rate of the cement increase simultaneously, and the adsorption rate of the water reducer molecules increases more. Obviously, this is reflected in the increase in the initial fluidity of the cement slurry. When the mixing water temperature is ≥ 40 ℃, the cement hydration rate significantly increases and gradually becomes a controlling factor. As a result, the net adsorption rate (adsorption rate minus consumption rate) of the water reducing agent molecules decreases, and the cement slurry also shows insufficient water reduction. Therefore, it is believed that the initial dispersion effect of the water reducer is best when the mixing water is between 20-30 ℃ and the cement slurry temperature is between 18-22 ℃.

When the discharge time is long, the expansion of cement slurry is consistent with the generally accepted conclusion. When time is sufficient, polycarboxylate water reducing agents can adsorb on cement particles at various temperatures until saturation occurs. But at low temperatures, cement hydration consumes less water reducing agents. Therefore, over time, the expansion of cement slurry will increase with the increase of temperature. Increase and decrease.

This experiment not only considered the influence of temperature, but also focused on the effect of time on the dispersion effect of polycarboxylate superplasticizer, making the conclusion more specific and closer to engineering practice. The conclusion drawn is as follows:

(1) At low temperatures, the dispersion effect of polycarboxylate superplasticizers has significant timeliness. As the mixing time increases, the fluidity of cement slurry increases. As the temperature of the mixing water increases, the expansion of the cement slurry first increases and then decreases. There may be significant differences between the state of concrete when it comes out of the machine and the state of concrete when it is poured on site.

(2) Heating the mixing water during low-temperature construction is beneficial for improving the flow hysteresis of concrete. During construction, attention should be paid to the control of water temperature. The temperature of cement slurry is between 18-22 ℃, and the flowability is the best when it is discharged from the machine. Prevent the phenomenon of reduced concrete fluidity caused by high water temperature.

(3) When the discharge time is long, the expansion of cement slurry decreases with the increase of temperature.

Rocommended Products

Related News About Construction Chemicals

English

English