Compatibility of Polycarboxylate Superplasticizer Liquid with Different Types of Cement

As an important admixture in modern concrete engineering, the compatibility of polycarboxylate superplasticizer liquid with different types of cement is directly related to the performance of concrete. In this paper, the compatibility between polycarboxylic acid-type high efficient water reducing agent liquid and different types of cement will be discussed in detail, in order to provide theoretical basis for the practical application of concrete engineering.

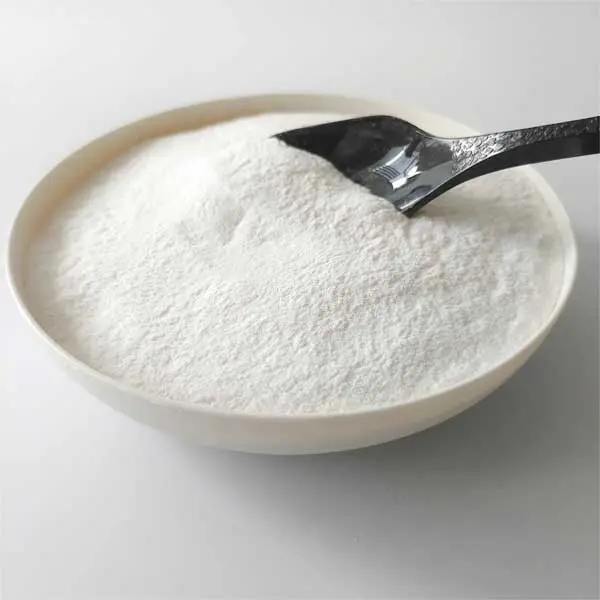

Overview of the characteristics of polycarboxylate superplasticizer liquid

With its unique molecular structure and performance characteristics, polycarboxylate superplasticizer liquid plays an important role in concrete engineering. Its molecular chain contains several carboxyl groups and polyoxyethylene functional groups, which gives the water reducing agent liquid good dispersibility and adsorption. These characteristics make the polycarboxylate superplasticizer liquid can effectively improve the working performance of concrete, and improve the strength and durability of concrete.

Characterization of different types of cement

As the main cementing material of concrete, cement is of various types, including silicate cement, ordinary silicate cement, slag silicate cement and so on. Different types of cement have differences in chemical composition, mineral composition and physical properties, which have an important impact on the compatibility of polycarboxylate superplasticizer liquid.

Discussion on the compatibility between polycarboxylate superplasticizer liquid and different types of cement

In practical application, the compatibility between polycarboxylate superplasticizer liquid and different types of cement varies. Silicate cement has better compatibility with polycarboxylate superplasticizer liquid due to its single chemical composition, which can give full play to the advantages of water reducing agent liquid. On the other hand, slag silicate cement and other cements containing more slag components may reduce the dispersing effect of the water reducing agent liquid due to the strong adsorption of the slag components to the water reducing agent liquid, thus affecting the performance of the concrete.

In order to improve the compatibility of polycarboxylate superplasticizer liquid with different types of cement, it can be achieved by adjusting the formula of the water reducing agent liquid, optimizing the proportion of concrete, and improving the mineral composition of cement. These measures can effectively improve the working performance and strength of concrete to meet the actual needs of the project.

Actual application case study

In the actual project, polycarboxylate superplasticizer liquid has been widely used. By testing and comparing the compatibility between different types of cement and polycarboxylate superplasticizer liquid, it is found that the reasonable selection and use of water reducing agent liquid can significantly improve the performance of concrete and project quality. Meanwhile, it also provides strong technical support for the design and construction of concrete projects.

In the field of Construction Chemical Products, Jufu Chemical shows unique brand advantages with its excellent R&D strength, product quality and innovation ability. The company's polycarboxylate superplasticizer liquid not only has excellent compatibility and stability, but also can significantly improve the performance of concrete and project quality. In addition, Jufu Chemical focuses on communication and cooperation with customers, providing personalized solutions and quality services, which has won wide recognition in the market.

To summarize, the compatibility of polycarboxylate superplasticizer liquidwith different types of cement is one of the key factors affecting the performance of concrete. Through in-depth study and exploration of its compatibility law, as well as reasonable selection and use of water reducing agent liquid, its advantages can be fully utilized to improve the performance of concrete and project quality. And Jufu Chemical, with its unique brand advantage, provides a strong guarantee for the efficient implementation of concrete projects.

Rocommended Products

Related News About Construction Chemicals

English

English