Knowledge Of Dispersant MF

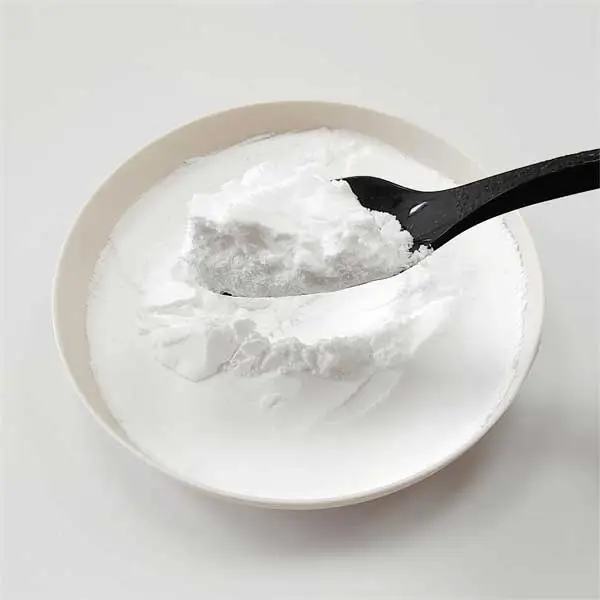

Dispersant MF is a widely used dye additive. It is mainly by methyl naphthalene or washing oil as raw material after sulfonation, hydrolysis, condensation with formaldehyde. An anionic surfactant produced by such steps as neutralization. Surfactants have the functions of solubilizing, wetting and permeating, dispersing and flocculating, foaming and defoaming, anticorrosion, washing, antistatic and so on. They are widely used in the production of fine chemical products.

When an external mechanical force acts on the dye aggregates, if the mechanical force is greater than the attraction between the dye aggregates, the dye aggregates will be destroyed and dispersed into primary particles. Dyes need to consume energy during the dispersion process, and the sanding process of the sand mill is the process that provides energy for the dye aggregates. The dye can be polished by a process of collision, squeezing or shearing between the dye aggregates and the medium. The common sanding medium is glass beads.

Under the action of mechanical force, the interaction between medium and dye aggregation, makes some aggregate divided and broken, but there are a large part of the aggregate only produces a tiny crack, hours after mechanical force when the outside world, the small crack in molecular inter-atomic forces and aggregate surface under the action of surplus value chain heal on its own. Therefore, it is necessary to constantly apply mechanical forces to the dye aggregates to gradually break up the cracked aggregates. If the dye dispersant is added to the grinding system, the dye dispersant particles will tip into the cracks of the dye aggregate under the wetting and adsorption action of the dye dispersant, so as to prevent the self-healing of these cracks, so as to achieve the purpose of dispersion.

To sum up, dispersant MF is mainly used as a dispersant and filler for vat dyes and disperse dyes, and is mainly used as a processing agent and dispersant in the grinding process of vat dyes and disperse dyes. Its performance is better than dispersant N. Dispersant MF has the following advantages: good grinding effect, dispersion, heat resistance and high temperature dispersion stability. Compared with powder N, it is high temperature resistant and stable. Dispersant MF can make dyes bright, strong and even in coloring. Dispersant MF can also be mixed with various dispersants to meet the commercial requirements of various disperse dyes and vat dyes. It can also be used as an early-strength water-reducing agent for concrete; it can be used as a dispersant for vat dye grinding and vat dye suspension dyeing. As well as latex stabilizers for the rubber industry and tanning agents for the leather industry.

Rocommended Products

Related News About Construction Chemicals

English

English